See you at the show!

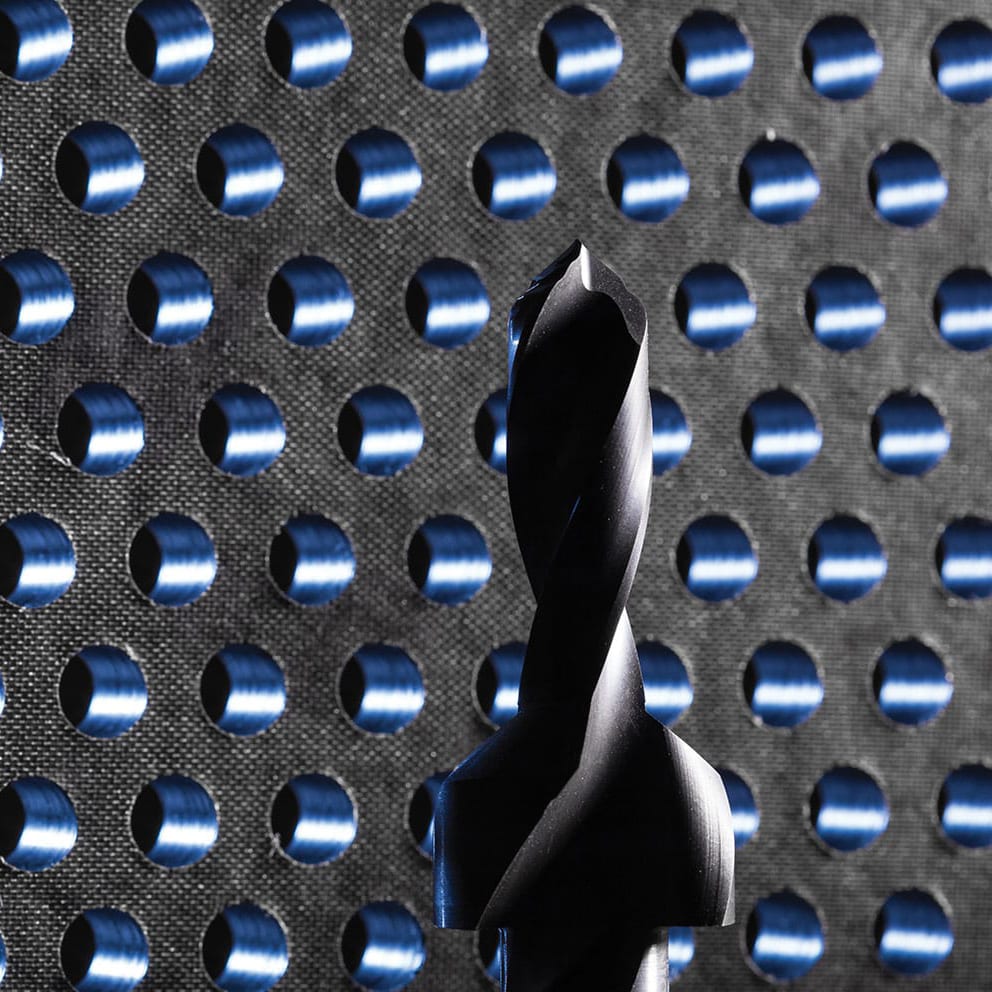

Come see us at CAMX booth E42 Oct 30 – Nov 2 where we’ll have carbon fiber panels showcasing our extremely exacting and precise holes made by our custom solid carbide drill using Wave-Point™ technology. We’d love to see you and discuss any opportunities or challenges you may have currently and if our drilling solutions may assist your machining & drilling production. Our main objective is to help customers drill better quality holes, and achieve the fastest cycle times in the industry!

Not going to the show? Schedule a call with our team

Where We Excel

Complex materials with challenging requirements, this is Sharon-Cutwell’s sweet spot. Simply put, we are experts at making precision holes in the toughest materials and applications.

Sharon-Cutwell developed Wave-Point™ Technology to solve the drilling challenges inherent to highly engineered carbon fiber composites. The study of the cutting process including hole quality, tolerances and tool life led to its innovative design, founded on a unique tool tip configuration that doesn’t simply cut carbon fiber, but rather carves the material in order to eliminate delamination. This dramatically minimizes exit burrs.

Wave-Point™ Technology—coupled with an exclusive diamond coating enables higher operating speeds and longer tool life. All of which help cut time out of manufacturing processes.

CUSTOMER SUCCESS STORY:

Boeing 777 Wing Project

Through extensive research and development efforts, Sharon-Cutwell found drilling solutions for Boeing’s 777 composite wings.

What Our Customers Have to Say

“Sharon-Cutwell has been our go-to resource for custom tooling. They have been extremely responsive to our needs and their quality is second to none.”

“I was in a bind, so I reached out to Cutwell looking for some custom carbide woodruff cutters, in a very short turn around. They were able to quote and design the tools within 24 hours, and offer me an expedited lead time to help me hit my turnkey runoff deadline, in a few short weeks.”

“Sharon-Cutwell has supported my team as we launched the drilling and assembly of our advanced composite 777X wing. It is their desire to provide truly innovative solutions and commitment to helping us solve our challenging problems that helped us be ready on day 1.”

“I was struggling with a difficult taper reamer application on our brake knuckle launch. I searched everywhere and couldn’t find someone who could solve it until Sharon-Cutwell developed an innovative solution that was very easy for me to implement. Now it works flawlessly!”

“We really appreciate the continuous learning attitude, drive for improvements, willingness to constantly increase your knowledgebase, thru the pushing of the envelope of our product.”